Media blasting is also referred to as sandblasting. There are different media types used to resurface an item, ranging from least aggressive to most aggressive. We use what is required to achieve the best results, in preparation to coating. Like with any coating process, the preparation of the material is the most important part to a long lasting durable coating. To ensure the highest quality of surface preparation, we’ve invested in state of the art sandblasting equipment. We have a large blast room that can accommodate items as long as 20 feet.

Visit our PORTFOLIO page to check out our work!

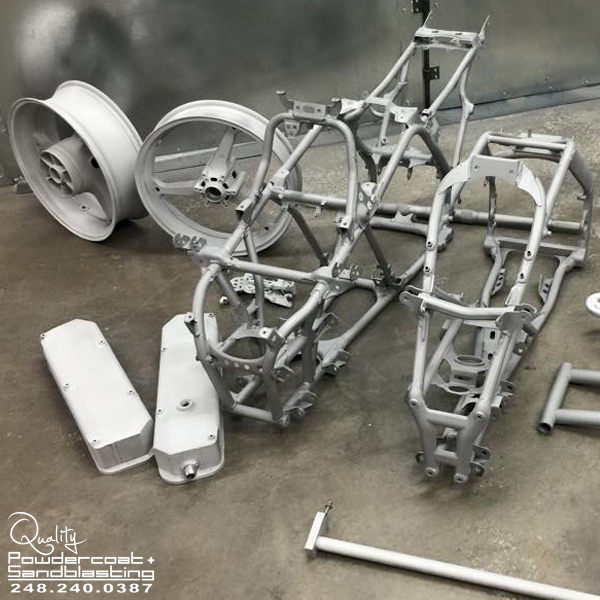

Powder coating is a thermoplastic or a thermoset polymer in a free flowing powder form that is applied to metal surfaces using an electrostatic gun. The polymer is then cured in an oven at 400ºf to create a highly durable coating that is superior to conventional painted coatings.

Visit our PORTFOLIO page to check out our work!

Ceramic coating is highly effective when used on engine and exhaust system components including exhaust headers, exhaust manifolds, turbochargers, tail pipes, valve covers, heat shields, and cylinder heads, helping to protect sensitive components from the effects of high heat. It also protects against oxidization and keeps your parts looking good. Our ceramic coating is protective up to 2000ºF.

Visit our PORTFOLIO page to check out our work!